The work method of C&W Snijtechniek

What happens with the received information

All the information that comes in, is digtally processed in the system. An offer can be made quickly, because the cutting time, the necessary equipment and the handling costs can be calculated very easily by the system. Digital drawings can be deliverd in almost any format, including in dxf, dwg, adobe illustrator and eps.

Short delivery times of waterjet cutted products

Because of the fixed contact there are short lines. Besides that the company is set on short delivery times. When an order is processed it is always handled in a proffessional and neat method.

Benefits of waterjetcutting

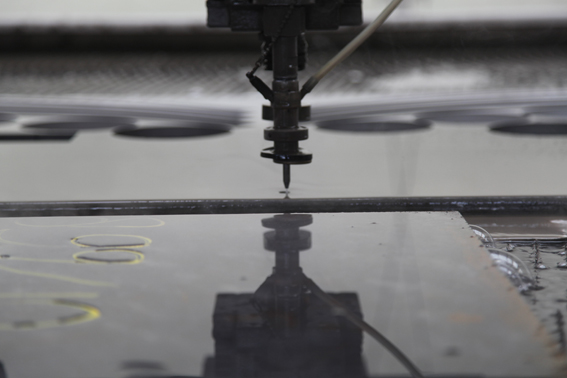

Once there is an agreement for the offer, the order goes directly to the work preparation. With the latest software the parts are as favorable as possible in the plate ‘nested’, so that loss of material is kept to a minimum. Due to the clever planning in the fully automated system short delivery times can be guaranteed. Entirely computer-controlled, the materials are cut. And after cutting there is no post-processing needed.

An overview of all the benefits of waterjetcutting at C&W Snijtechniek entails can be found here.

Qualitative waterjetcutting

Quality is our priority. The quality is constantly monitored by our highly trained staff. From random till a 100 precent if desired.

Supply of waterjet cutted products

The products are clean and dry packed, and go before shipping through a fully automated car wash if needed. Depending on the amount and speed in which the delivery should occur, the order is deliverd with own transport or by courier to the customer.